Home Page Project Description Process Final Design

The pressure vessel was constructed based on a fairly simple design. The main body consists of an aluminum cylinder with aluminum plates welded onto the ends, sealing the vessel. To enable filling of the vessel with DME or other liquids or gasses (based on need) 4 holes were drilled into the vessel and tapped with 1/4 in. pipe thread. This allows a variety of different apparatuses to be attached to the vessel. A second was made the same way with a glass top at the top for any future needs.

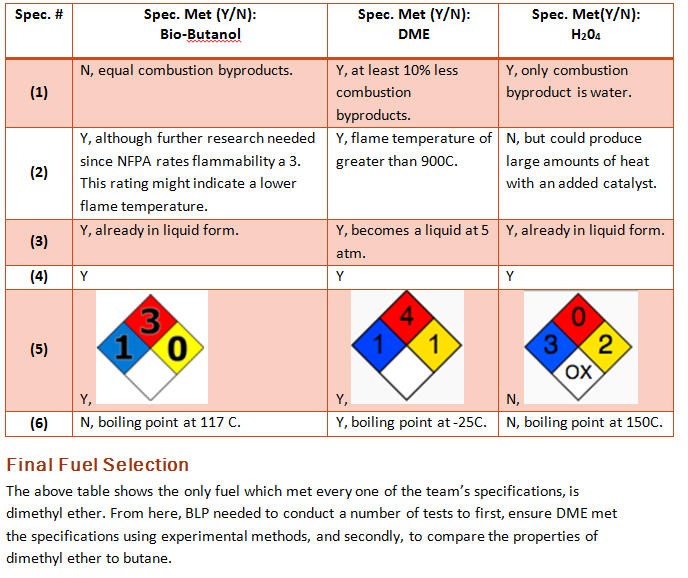

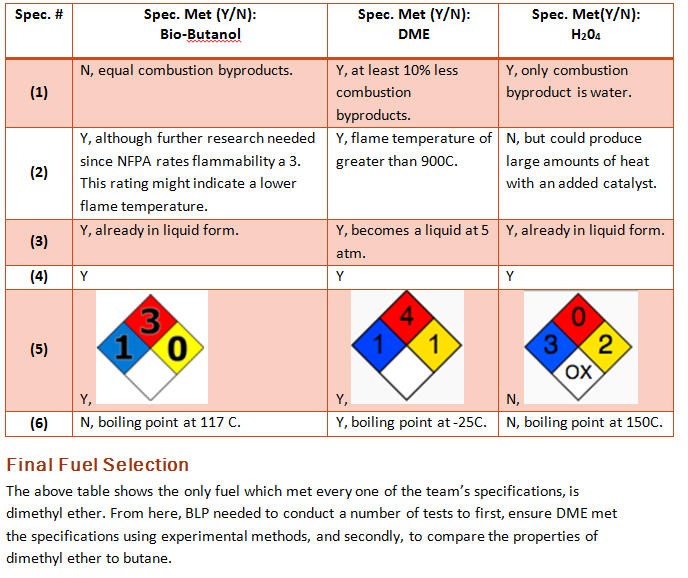

In conclusion, current lighters have many concerns that need to be addressed. There are many opportunities to improve current lighters to make the lighter safer, healthier and cleaner. The team found dimethyl ether is the foundation to achieving a new cleaner, safer, healthier lighter, and cost competitive lighter.

As our client ventures forward to continue his work on creating a new lighter, the team recommends continuing the step process beyond the fuel section, and onto the ignition and casing designs. For future work on the Better Lighter Project the team recommends the following:

The team realized the original goal of constructing a ‘is like’ prototype by then end of the school term was impossible to complete given the project’s timeline of completion by Spring 2012. Through this realization the team readjusted the problem statement and the projects goals to reflect the realistic timeline.