There are many tasks involved in this project in order to develop a successful end product for Benefit Studios. The client’s overall project goal is obvious; design a superior disposable lighter while remaining cost competitive in the disposable lighter market. On the contrary, the team was to research if and how current disposable lighters could be improved, and then begin on the first part of the lighter resign: choose a new fuel and prove the fuel would act as a suitable replacement for butane.

There are opportunities to make improvements on current lighters.

•Safety is where most impactful improvements can be made.

•Only 10% of lighters sold in the United States adhere to the regulations set by American Standards for Testing and Materials (ASTM) or International Organization for Standardization (ISO). BIC is only company which sells lighters in United States that are ASTM/ISO compatible.

•Adhering to these standards will allow our lighter to be competitive in the lighter market. It is speculated the United States to follow Canada and other European countries, and will soon prohibit the sale of lighters which do not adhere to ASTM or ISO regulations.

•Adhering to safety standards will also prevent lighter malfunctions and potential user injury.

•Other fuels exist which are better suited for lighter use while also be environmentally friendly. Butane is current produced as a byproduct of the oil refinement process.

•There are more sustainable options for casting and ignition materials. Current disposable lighters are not recyclable unless the lighter is taken a part and components are recycled individually.

•Design functionality can be improved. One example of improving the lighter design would be to prevent the user from being burned by flame when inverting the lighter when igniting a candle.

•Emit 10% less byproducts than butane

•Steady state flame temperature > 451F

•Can compress into liquid with vapor pressure < 7 atm at 21 C

•Shipping procedures only require flammable gas precautions.

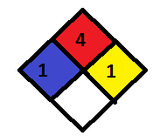

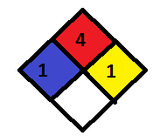

•National Fire Protection Association (NFPA) regulation must not exceed

•Material non-reactive

•Airtight up to 175 psi

•Must allow visual observation

•Modular : ability to add and remove components

•Ability to simulate temperatures of lighter environments, ranging from -20F to 130F

- Research on existing Lighters

- Research on Fuels

- Choosing a fuel

- Designing Test apparatus

- Make Test apparatus

- Test current fuel and Test DME

- Compare testing